Screw Press– FAQ

1 What is a Multi Plate Screw Press?

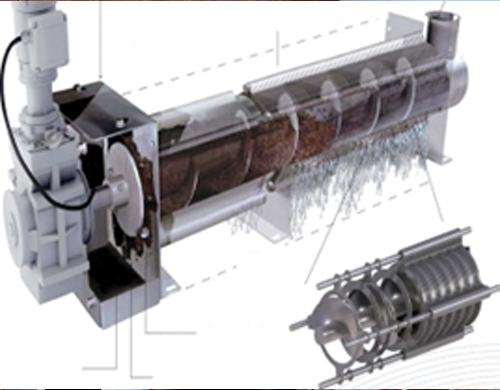

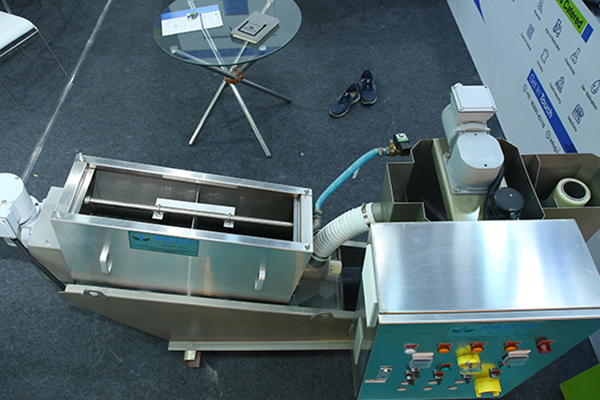

A Multi Plate Screw Press is a specialized piece of equipment designed for efficient solid-liquid separation. It uses a series of rotating plates and screws to dewater sludge or other materials, removing excess moisture and producing a drier, more manageable solid.

2. How does the Nirtech Multi Plate Screw Press work?

The press operates by feeding the material into a chamber containing rotating plates and screws. As the screws rotate, they exert pressure on the material, forcing the liquid through a filter medium while retaining the solid.

3. What are the advantages of using a Nirtech Multi Plate Screw Press?

High Throughput: Handles large volumes of material efficiently.

Low Power Consumption: Operates with minimal energy use.

Clog-Free Operation: Minimizes downtime due to blockages.

Automated Control: Enables 24/7 operation with minimal supervision.

Low Maintenance: Requires minimal maintenance and repairs.

Reduced Sludge Volume: Significantly reduces the volume of sludge for easier disposal.

4. What types of sludge can be dewatered with this press?

The Nirtech Multi Plate Screw Press can effectively dewater a wide range of sludge types, including: Municipal wastewater sludge, Industrial wastewater sludge, Biosolids, Food processing sludge, Chemical process sludge.

5. What are the key applications of the Multi Plate Screw Press?

Municipal wastewater treatment plants, Industrial wastewater treatment facilities, Food and beverage processing plants, Chemical and pharmaceutical industries, Agricultural applications (manure dewatering).

6. How does the Multi Plate Screw Press compare to other dewatering technologies?

Compared to traditional methods like belt filter presses and centrifuges, the Multi Plate Screw Press offers advantages such as: Lower energy consumption, Higher throughput, Reduced maintenance requirements, Improved dewatering efficiency.

7. Is the Multi Plate Screw Press easy to maintain?

Yes, the Multi Plate Screw Press is designed for easy maintenance. Regular inspections and basic cleaning are typically sufficient to ensure optimal performance.

8. How can I learn more about the Nirtech Multi Plate Screw Press?

Visit the Nirtech website for detailed product information. Contact Nirtech directly to speak with a sales representative. Request a customized quote for your specific dewatering needs.

9. Does Nirtech offer installation and training?

Yes, Nirtech provides professional installation and comprehensive training to ensure proper operation and maintenance of the Multi Plate Screw Press.

10. What are the environmental benefits of using a Multi Plate Screw Press?

Reduces sludge volume, minimizing landfill space requirements. Improves sludge quality for beneficial reuse (e.g., fertilizer). Contributes to a reduced environmental footprint by minimizing energy consumption.